Here are 5 ways to help improve and maintain crane safety. Are you being a safe operator? Here is a guide with great safety tips to apply to your daily safety plan.

Nevertheless, cranes increase danger and safety risks. Mobile cranes not only move or lift heavy loads. However, they involved frequently are in operating at great heights. Crane operators must have essential skills, knowledge with updated crane certification and always be cautious when operating cranes.

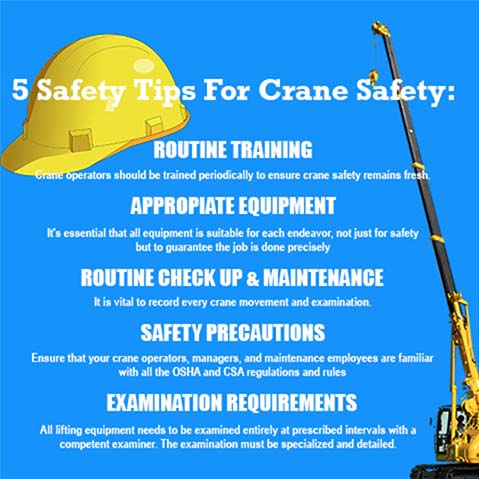

5 Safety Tips for Crane Safety

Routine Training

Brand new hires who'll operate cranes should be trained and most of the crane operators must be routinely trained periodically to ensure crane safety remains fresh. Anytime there are changes in equipment, regulations, or procedures, employed crane operating staff should be routine trained on all fluctuations.

The practice should go beyond test preparation training, certification and give operating staff an idea of real-life situations. Constantly learning and preparing for actual situations that an operator can prevent just by being safe. Be sure that the trainer understands your organization as well as your equipment. We can't stress enough when training the instructor's point is clear for the employees to understand.

Appropriate Equipment

It's essential that the current equipment is appropriate and suitable for each endeavor, not just for safety but to guarantee the job is done precisely. This includes utilizing the right type of crane as well as all other appropriate equipment attachments such as slings, chains, ropes, and wires.

Routine Check Up and Maintenance

Just as with all other gear and equipment, routine checkup and maintenance attention is very important. Employing worn out, broken, or compromised equipment is still a recipe for either injury or worse. The repairs for cranes and other equipment maintenance needs to be scheduled. It's also wise to have an agenda in place to handle issues as they appear for service. It is vital to record every crane movement when inspecting.

Safety Precautions

Your purpose must be to maximize safety precautions for the workers as well as other safety measures within inspections. Ensure that your crane operators, managers, and maintenance employees are familiar with all the OSHA and CSA regulations and rules. Pay special attention to your fall protection strategy.

Your safety measures need to not merely take in to account your crane workers, nevertheless also the general public and different non-crane owner-employees. Post your safety procedures in prominent places your employees may view often. Give cards together with your safety procedures to every employee and have them examine them before each shift. You can never be too safe.

Examination Requirements

You are held to strict legal requirements when it involves crane examination requirements. All lifting equipment needs to be examined entirely at prescribed intervals with a competent examiner. The examination must be specialized and detailed.

Operators Duty

It is the trained operator's duty to do the daily inspection routine and use good sense to maintain crane safety. You can never be too safe when working with cranes. Accidents are simple to happen. The harm and injury of accidents can turn out to be severe or even fatal.

Your Never to Safe With Cranes

When it comes to using cranes you may never be too safe. appropriate checkups with a sense of precautions can prevent accidents. safety is everyone's safety. Safety should be part of everyone's business if in the crane industry or not. These 5 excellent safety tips can possibly help or even save lives

Take these safety tips to use them in an ideal way but don't quit there apply them to your daily safety routine.