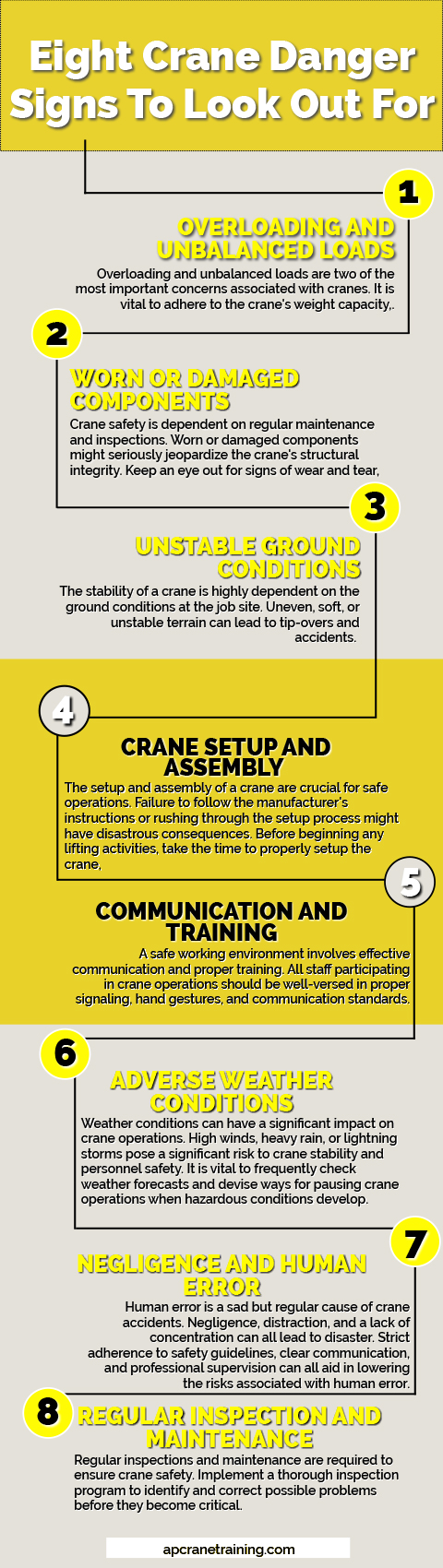

If you work near cranes, keep an eye out for the eight crane danger signs of improper operation. If you detect any of these on a job site, inform a supervisor immediately to avoid a disaster.

Cranes play a crucial role in the fast-paced world of construction and heavy machinery. These massive towers, with their incredible lifting powers, are essential for a number of industrial applications. However, it is vital to be aware of potential crane dangers in order to ensure job site safety. In this extensive guide, we will go through eight crucial crane risk indicators that you should always be on the lookout for. Understanding these warning signs allows you to decrease risks, avert accidents, and prioritize the well-being of everyone involved.

1. Overloading and Unbalanced Loads

Overloading and unbalanced loads are two of the most important concerns associated with cranes. It is vital to adhere to the crane's weight capacity, as exceeding it could have disastrous consequences. To avoid any imbalances that could endanger stability, make sure the load is evenly distributed and firmly fastened.

2. Worn or Damaged Components

Crane safety is dependent on regular maintenance and inspections. Worn or damaged components might seriously jeopardize the crane's structural integrity. Keep an eye out for signs of wear and tear, such as frayed cables, rusted parts, or defective controls. Addressing these concerns as soon as feasible will help to prevent accidents caused by device failure.

3. Unstable Ground Conditions

The stability of a crane is highly dependent on the ground conditions at the job site. Uneven, soft, or unstable ground conditions can lead to tip-overs and accidents. Before utilizing a crane, be sure the ground can support the weight and movement of the apparatus. If necessary, use proper ground stabilization methods to reduce risks.

4. Crane Setup and Assembly

The setup and assembly of a crane are crucial for safe operations. Failure to follow the manufacturer's instructions or rushing through the setup process might have disastrous consequences. Before beginning any lifting activities, take the time to properly setup the crane, ensuring that all components are firmly linked and that the crane is level and sturdy.

5. Communication and Training

A safe working environment involves effective communication and proper training. All staff participating in crane operations should be well-versed in proper signaling, hand gestures, and communication standards. Regular training sessions should be held to update material and keep everyone up to date on the most recent safety concerns.

6. Adverse Weather Conditions

Weather conditions can have a significant impact on crane operations. High winds, heavy rain, or lightning storms pose a significant risk to crane stability and personnel safety. It is vital to frequently check weather forecasts and devise ways for pausing crane operations when hazardous conditions develop.

7. Negligence and Human Error

Human error is a sad but regular cause of crane accidents. Negligence, distraction, and a lack of concentration can all lead to disaster. Strict adherence to safety guidelines, clear communication, and professional supervision can all aid in lowering the risks associated with human error.

8. Regular Inspection and Maintenance

Regular inspections and maintenance are required to ensure crane safety. Implement a thorough inspection program to identify and correct possible problems before they become critical. This proactive method will not only increase safety, but will also extend the equipment's lifespan, ensuring top performance.

Conclusion

Safety should always be the top priority in crane operations. By familiarizing yourself with these eight crane danger signs and taking appropriate preventive measures, you can significantly reduce the risk of accidents and create a safe working environment. Remember, adhering to load capacities, proper equipment maintenance, thorough inspections, and effective communication are crucial elements for ensuring crane safety. By being observant and proactive in identifying and addressing potential crane dangers, you can protect the well-being of workers and prevent costly accidents.

Remember that everyone is responsible for crane safety, from operators and supervisors to project managers and ground employees. You may create a work environment where everyone understands and respects the possible hazards associated with cranes by fostering a culture of safety and stressing constant training and education.